Precast concrete, as the name implies, is a construction material that is prepared, cast, and cured off-site and then transported to the job site. This material offers a smart solution that keeps your project on track while saving money. In this article, Garrett Precast—a reputable precast company—looks into how precast concrete saves time on the job site.

Reduced On-Site Construction Time

One of the most obvious ways precast concrete saves time is by minimizing on-site work. Since the elements are manufactured off-site, the construction team can focus on assembly rather than waiting for forms to be built and concrete to cure. Installation involves simply lifting the precast pieces into place and securing them, reducing the overall project timeline. This is particularly valuable for large-scale projects, such as commercial buildings, bridges, and parking structures, where traditional methods could add weeks or even months to the schedule.

Faster Curing and Consistent Quality

Curing is a critical step in concrete construction, as improper curing can lead to cracks, weak spots, and delays. Precast concrete is cured in a controlled environment with optimal temperature, humidity, and quality control measures. This ensures that every piece meets the required specifications and strength standards before it even arrives on-site, eliminating the waiting time associated with on-site curing. With consistent, factory-controlled quality, the risk of costly rework or on-site inspection failures is also reduced.

Simplified Site Logistics

Precast concrete also improves overall project efficiency by streamlining site logistics. Since large portions of the structure are delivered ready to install, there is less need for extensive scaffolding, formwork, and on-site concrete mixing. This reduces the number of trades working simultaneously on-site, lowers congestion, and allows for better scheduling of other tasks. In short, construction can proceed smoothly without the bottlenecks often encountered with cast-in-place concrete.

Reduced Weather Delays

Weather can slow down traditional concrete work. Rain, extreme temperatures, and high humidity can delay pouring, curing, and finishing processes. Precast concrete mitigates these risks because the majority of production happens in a factory setting, independent of weather conditions. Installation can continue on-site as soon as conditions are safe, reducing costly downtime.

So, there you have it. These are some of the ways in which precast concrete can save time on the job site. However, it’s best to work with a dependable precast company in order to realize the full benefits. As you may know, all precast companies are not created equal. A trusted company with a proven record can deliver concrete precast products on time and provide the support needed to keep your project on schedule.

Contact Garrett Precast for Quality Precast Concrete Products

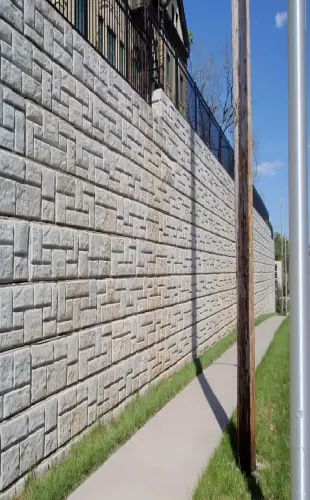

At Garrett Precast, we are renowned for manufacturing and supplying high-quality precast concrete products in a timely manner. Every product we manufacture meets the highest quality standards thanks to our investment in the latest technology and state-of-the-art facilities. Contact Garrett Precast today if you’re looking for quality concrete precast products. From retaining walls in Anderson, SC and seawalls to concrete parking stops and septic tanks, we’ve got you covered. We’ll help you keep your project on track, save you money, and guarantee structures that stand the test of time.