At Garrett Precast, we specialize in offering a wide range of precast solutions, including retaining walls, seawalls, concrete parking stops, and many more. In this post, we’ll discuss why infrastructure projects are moving toward precast concrete.

Durability and Long-Term Performance

This is arguably one of the major reasons why contractors prefer precast solutions. Infrastructure elements such as bridges, culverts, tunnels, and utility structures must withstand heavy loads, extreme weather, and constant use for decades. Concrete precast products are manufactured in controlled factory environments, where there’s precise mixing, curing, and quality control. This results in higher strength, improved resistance to cracking, and better long-term performance compared to many cast-in-place alternatives.

Faster Construction and Reduced Downtime

Because components are produced off-site while site preparation is underway, overall project timelines are reduced. Once delivered, precast elements can be installed quickly using cranes and minimal on-site labor. This is especially beneficial for projects that affect traffic flow, utilities, or public access, where minimizing disruption is required. As long as you work with a trusted precast company, you can count on precise manufacturing, reliable delivery schedules, and high-quality components that help keep your infrastructure project on track and within budget.

Consistent Quality and Design Flexibility

Precast concrete offers unmatched consistency due to factory-controlled production processes. Uniform dimensions and consistent finishes ensure proper fit and alignment across large-scale projects. At the same time, precast solutions provide design flexibility; hence, they allow for customization in shape, size, load capacity, and surface finish to meet specific engineering and architectural requirements.

Sustainable and Environmentally Responsible Construction

Precast manufacturing minimizes material waste, improves energy efficiency, and allows for the incorporation of recycled materials. In addition, the long service life of precast components reduces the need for frequent repairs or replacements, lowering the overall environmental impact over time. Using concrete precast products is not just good for the pocket; it also promotes environmental sustainability.

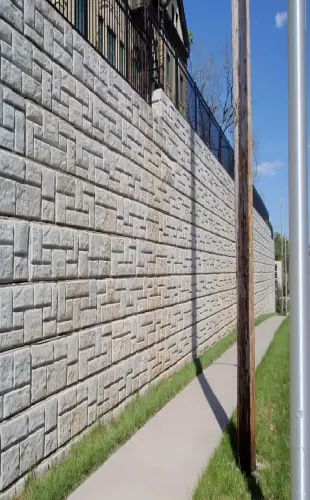

Wide Range of Infrastructure Applications

Precast solutions are used across a broad range of infrastructure projects. In fact, it has become a common sight in modern construction to see precast concrete components used for bridges, highways, drainage systems, utility structures, and more. Some of the common applications include bridge girders and deck panels, box culverts and stormwater systems, manholes and utility vaults, retaining walls in Greenville, SC, sound barriers, and transit structures. In marine and coastal environments, precast concrete is commonly used for seawalls, docks, and breakwaters due to its resistance to corrosion and wave forces.

Reach Out to Garrett Precast for Quality Precast Solutions

There’s no doubt that precast concrete has become a transformative force in infrastructure development. By offering consistent quality, cost savings, and time savings, it’s easy to see why it’s a game changer in the construction industry. If you’re looking for a trusted precast company, get in touch with Garrett Precast. We pride ourselves on delivering durable concrete precast products for infrastructure projects at budget-friendly prices. We never cut corners during manufacturing and always deliver products on time. Contact us today to discuss your infrastructure project and let us provide you with quality products that will meet your needs and stand the test of time.