At Garrett Precast, we’re passionate about manufacturing and supplying quality concrete precast products. Our goal is to help our clients achieve a fast completion time and structures that stand the test of time while keeping costs low. If you’re looking for a dependable precast company, we’re one phone call away. Let’s look at some of the ways precast concrete can reduce on-site construction disruptions.

-

Faster Installation and Shorter Project Timelines

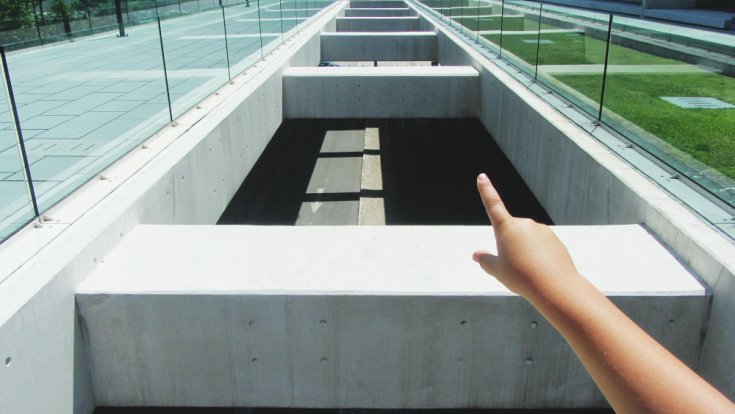

Because components such as walls, beams, columns, and slabs are fabricated in advance, on-site work is limited to installation rather than lengthy forming, pouring, and curing processes. This can shorten construction schedules. Faster project completion means fewer days of heavy equipment on-site, reduced labor hours, and less interference with surrounding businesses, residents, or traffic.

-

Reduced Noise and Dust on the Job Site

Traditional concrete work generates noise and dust from mixing, pouring, vibrating, and finishing concrete. Precast concrete minimizes these activities on-site. Since the manufacturing process happens off-site at the precast company premises, there is far less grinding, cutting, and formwork assembly at the construction location. This reduction in noise and airborne dust creates a safer, cleaner, and more community-friendly job site, which is especially important in urban areas or near occupied buildings.

-

Fewer Weather-Related Delays

Weather is a common cause of construction disruptions. Rain, extreme temperatures, or high winds can delay cast-in-place concrete work and affect curing quality. Precast concrete is produced indoors under controlled conditions; hence, it eliminates weather-related production delays. On-site installation can proceed in a wider range of weather conditions to keep projects on schedule and reduce costly downtime.

-

Improved Site Safety and Organization

With fewer on-site construction steps, job sites using precast concrete tend to be more organized and safer. Reduced formwork, fewer materials stored on-site, and less wet concrete handling lower the risk of accidents and injuries. A more streamlined site allows crews to work more efficiently and reduces disruptions caused by safety incidents or site congestion.

-

Less Traffic and Material Handling

Cast-in-place concrete requires frequent deliveries of raw materials such as cement, aggregates, water, and reinforcement. Precast construction reduces the number of deliveries, as finished components arrive ready to install. Fewer trucks coming and going helps minimize traffic congestion, road wear, and disruptions to neighboring properties. This is especially beneficial in dense urban environments or active commercial areas.

-

Consistent Quality with Minimal Rework

Precast concrete elements are manufactured under strict quality controls, ensuring consistent strength, dimensions, and finishes. Higher quality components mean fewer on-site adjustments, repairs, or rework. This reliability helps prevent schedule delays and reduces the disruptions that occur when mistakes need to be corrected during construction.

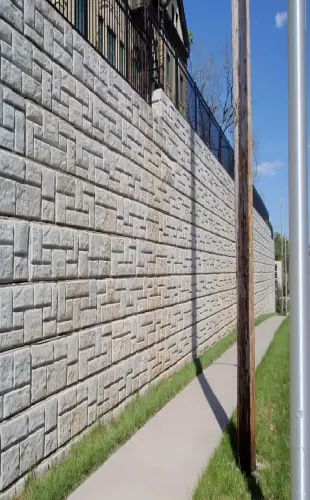

Contact Garrett Precast Today for Quality Concrete Precast Products

Opting for precast concrete in your construction projects can save you time, reduce site disruptions, and save you money. Remember, not all precast companies provide quality products. Garrett Precast is the name you can rely on when you need quality precast solutions at budget-friendly rates. We offer a wide range of products, including retaining walls in Greenwood, SC, seawalls, septic tanks, lift stations, concrete parking stops, and many more. Our team will collaborate with you to design and manufacture precast products that suit your needs. Contact us today, and let us discuss how precast concrete can speed up your next project!