Today, Garrett Precast—a reputable precast concrete company—looks into the common challenges when using precast and how to overcome them.

Challenge 1: Transportation and Handling Issues

One of the biggest challenges with precast elements is transporting large, heavy components from the manufacturing facility to the job site. Improper handling can cause cracking, surface damage, or alignment problems.

How to overcome it:

Careful planning is essential. Work with experienced precast suppliers who understand load limits, proper rigging, and transportation requirements. Using the correct lifting equipment and following manufacturer-recommended handling procedures reduces the risk of damage. Early coordination between the supplier and contractor helps avoid surprises on delivery day.

Challenge 2: Limited Design Flexibility

Precast components are manufactured in molds, which can limit last-minute design changes. Once pieces are produced, modifying them on-site can be difficult and costly.

How to overcome it:

Finalizing designs early is key. Involve precast engineers during the design phase to ensure components meet both structural and architectural requirements. Using Building Information Modeling (BIM) can help identify conflicts before production begins. When flexibility is needed, modular designs or adjustable connections can offer solutions.

Challenge 3: Site Coordination and Scheduling

Precast construction relies heavily on precise scheduling. Delays at the job site, such as unfinished foundations or crane availability issues, can disrupt delivery and installation.

How to overcome it:

Strong project coordination minimizes scheduling problems. Establish clear timelines for foundation completion, deliveries, and crane operations. Regular communication between the general contractor, precast manufacturer, and installation crew ensures everyone is aligned. Having contingency plans for weather or site delays also helps keep the project on track.

Challenge 4: Connection and Tolerance Issues

Precast components must fit together accurately. Even small tolerance issues can cause alignment problems, leading to installation delays or structural concerns.

How to overcome it:

Accurate surveying and proper foundation placement help ensure components fit as intended. Using standardized connection systems and performing quality checks before delivery reduces the risk of misalignment. Skilled installation crews also play a major role in addressing minor adjustments on-site.

Challenge 5: Perceived Higher Initial Costs

Some projects view precast as more expensive upfront compared to traditional cast-in-place concrete. This perception can discourage its use, even when long-term benefits exist.

How to overcome it:

Evaluating total project cost rather than just material cost provides a clearer picture. Precast often reduces labor, shortens construction schedules, and minimizes rework. These savings can offset higher initial expenses. Presenting a lifecycle cost analysis helps stakeholders understand the long-term value of precast construction.

Challenge 6: Weather and Site Constraints

While precast manufacturing occurs off-site, installation can still be affected by weather conditions or tight job sites, especially in urban areas.

How to overcome it:

Plan installations during favorable weather windows whenever possible. Pre-installation meetings and site logistics planning help address space constraints. Because precast reduces on-site curing time, it can actually limit weather-related delays compared to traditional methods when planned correctly.

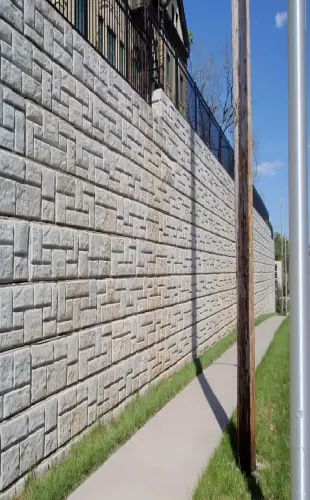

Contact Garrett Precast for Reliable Concrete Precast Products

Looking for high-quality concrete precast products? Contact Garrett Precast today. We are a local precast company that manufactures and supplies a wide range of products, including retaining walls in Greenville, SC, seawalls, septic tanks, septic risers, concrete parking stops, and many more. We combine top-quality materials with modern technology to deliver strong and long-lasting products. Our commitment to providing quality products and delivering them on time has enabled us to build lasting solutions with all our clients. Contact Garrett Precast today to place your order for concrete precast products.