Garrett Precast is a top-rated precast company that manufactures and supplies precast concrete products. Today, we’ll talk about how precast concrete is made.

Designing the Blueprint

The process begins long before any concrete is poured. Engineers and designers work together to create detailed plans for each precast element, whether it’s a wall panel, beam, slab, or decorative façade. These designs take into consideration the structure’s weight load, reinforcement needs, and the specific dimensions required for the project. Because precast components must fit together perfectly during installation, attention to detail is important. Every element is calculated to ensure it performs exactly as intended once it arrives on the jobsite.

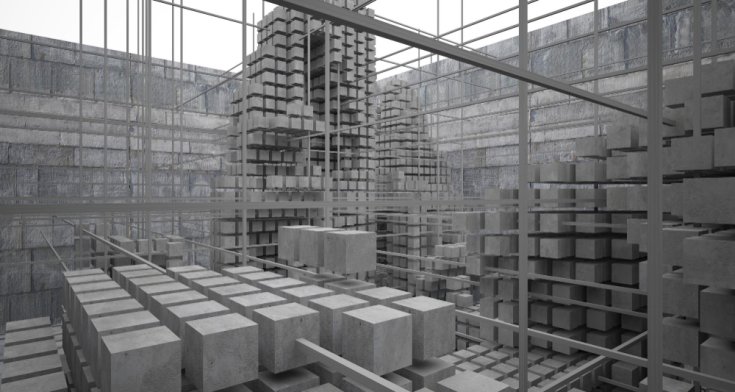

Preparing the Molds

Once the design is finalized, the next step is preparing the molds, known as forms. These molds can be made of steel, fiberglass, rubber, or wood depending on the shape and finish desired. The molds are thoroughly cleaned and treated with release agents so the concrete can be removed easily once it hardens. The quality of the molds is critical; even minor imperfections can affect the final product. Reinforcing steel, or rebar, is then placed inside the mold to give the precast piece added strength and structural integrity.

Mixing and Pouring the Concrete

With the molds ready, the concrete mixing begins. Because precast concrete is made in a controlled environment, the mixture can be tailored to meet exact specifications. Factors such as water-to-cement ratio, type of aggregate, additives, and curing time are carefully adjusted to produce the right consistency and strength. Once mixed, the concrete is poured into the molds, often using vibration techniques to remove air pockets and ensure even distribution. This step is crucial for achieving the dense, uniform structure that gives precast concrete its exceptional durability.

Curing Under Controlled Conditions

Curing is the process that allows concrete to harden and gain strength. In a precast facility, curing takes place under optimal conditions, often using heat, steam, or controlled humidity to accelerate and improve the process. This controlled curing not only speeds up production but also produces stronger and more consistent results than concrete cured outdoors. Depending on the type of precast component, curing can take anywhere from several hours to several days.

Quality Control and Finishing

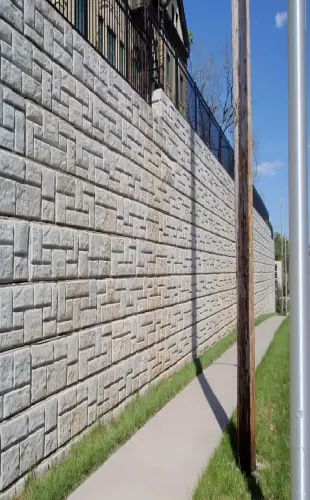

After curing, the precast pieces are carefully removed from their molds and undergo a thorough quality inspection. Technicians check for cracks, surface imperfections, and structural accuracy. If any finishing touches are needed, such as smoothing rough spots, adding textures, or applying sealants, this is the stage where it happens. Precast concrete can be customized with colors, finishes, and patterns, allowing it to meet both structural and aesthetic requirements.

Looking for Quality Concrete Precast Products? Contact Garrett Precast Today

Garrett Precast is the company to call when you need durable and affordable concrete precast products. We offer a wide range of products, including retaining walls in Anderson, SC, seawalls, septic tanks, lift stations, and many more. Our products are manufactured to meet the highest standards of quality and performance. Our goal is to meet and even exceed our clients’ needs, thereby building lasting relationships built on trust and reliability. Contact us today to learn more about the products we offer.