Today, Garrett Precast—a reputable precast company—looks into some of the common precast concrete applications. Read on to learn more about why precast concrete is taking over the construction industry and becoming the go-to choice for builders and property owners.

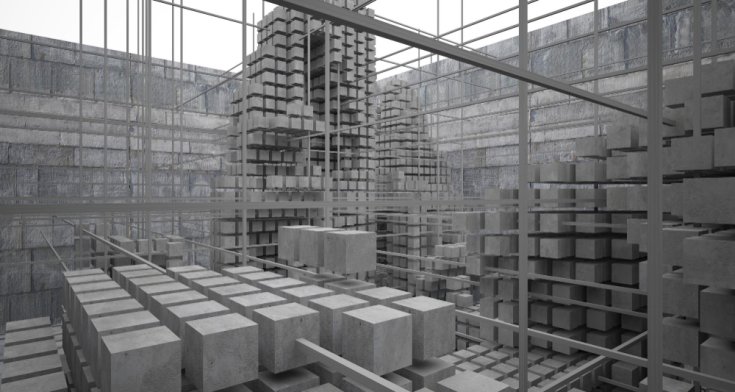

- Parking Garages and Commercial Buildings

Parking garages are one of the most common examples of precast concrete in action. The material’s inherent strength and durability allow it to withstand heavy loads, frequent traffic, and exposure to the elements. Precast beams, columns, floor slabs, and wall panels are manufactured off-site, ensuring tight quality control and faster assembly once delivered. This efficiency reduces project timelines, minimizes disruptions, and cuts down on labor costs. In addition to structural performance, precast concrete provides excellent fire resistance and sound insulation. These qualities make it a preferred choice for commercial buildings and multi-level garages.

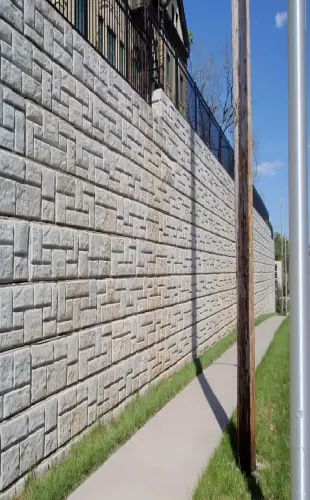

- Retaining Walls and Landscaping Structures

Precast retaining walls in Greenwood, SC have become a go-to solution for managing elevation changes and preventing soil erosion. These structures combine functionality with aesthetic flexibility, as they can be produced in a variety of finishes, textures, and colors to complement surrounding environments. Whether used along highways, in residential developments, or for terraced gardens, precast retaining walls provide stability and visual appeal. Because the sections are precast and cured before delivery, installation is quick, and the results are long-lasting with minimal maintenance required.

- Infrastructure and Transportation Projects

Precast concrete plays a crucial role in infrastructure projects such as bridges, tunnels, and culverts. The controlled manufacturing process ensures each component meets certain specifications and structural standards. Precast bridge girders and panels, for example, are designed to handle immense weight and stress, while precast sound barriers along highways reduce noise pollution for nearby communities. Since these elements can be installed rapidly, contractors can shorten project timelines, keeping roads and transit systems open with fewer interruptions.

- Water Management and Utility Systems

From stormwater drains and manholes to septic tanks and culverts, precast concrete is an essential material in water management systems. Its resistance to corrosion and chemical exposure makes it ideal for handling wastewater and runoff, ensuring long-lasting performance in even the most demanding environments. Municipalities prefer concrete precast products because they meet strict safety and environmental standards while offering easy installation and low maintenance over time.

- Marine and Coastal Construction

In coastal and marine environments, precast concrete is used to create seawalls, docks, and bulkheads that protect shorelines from erosion and wave impact. The material’s density and resistance to saltwater damage make it perfect for long-term use in marine construction, where durability and stability are needed.

Contact Garrett Precast for Quality Concrete Precast Products

Believe it or not, precast companies are not created equal. Some are known to go the extra mile to supply high-quality products that meet customers’ expectations. On the other hand, fly-by-night suppliers are more likely to deliver substandard products that will end up in disaster. Here at Garrett Precast, we pride ourselves on manufacturing and supplying reliable concrete precast products at competitive prices. From concrete parking stops and retaining walls to seawalls and lift stations, we’ve got you covered. Our products meet the highest quality standards and represent the forefront of precast technology. Contact us today to learn more about our products.

.webp)