In this blog post, Garrett Precast—a premier precast company—explains how precast concrete helps reduce construction delays. As a company that specializes in manufacturing concrete precast products, we understand the crucial role that precast concrete plays in the construction industry.

Off-Site Manufacturing Eliminates Weather Delays

Precast concrete solves construction slowdowns by shifting production indoors. Components are cast, cured, and stored in climate-controlled facilities, unaffected by weather conditions. This means foundations, walls, beams, and panels arrive ready to install. Even if rain clouds roll in, installation can often continue as planned, drastically reducing downtime.

Faster Installation and Assembly

Precast concrete is designed for efficiency. Once components arrive at the site, crews can install large sections using cranes and minimal labor. Unlike traditional concrete methods, which require formwork, reinforcing, pouring, curing, and stripping, precast elements are already complete.

This streamlined assembly process can shave weeks or even months off a project schedule. Buildings can go from foundation to fully enclosed structure in remarkably short timeframes.

Reduces Labor Requirements on Site

Labor shortages are a growing concern in the construction industry. Precast construction reduces dependence on skilled labor on-site by moving much of the work to the factory. In the manufacturing facility, teams are highly trained, processes are standardized, and productivity is consistent.

On-site, fewer workers are needed, and tasks become more predictable and manageable. With less risk of labor bottlenecks, projects move forward without the slowdowns caused by crew shortages or scheduling conflicts.

Improved Quality Control Prevents Costly Rework

Rework is one of the leading causes of construction delays and one of the most expensive. Precast concrete is produced under strict factory-controlled conditions. Mold systems, curing conditions, and reinforcement placement are carefully monitored to meet exact specifications.

Higher-quality components mean fewer on-site mistakes, adjustments, or structural issues. When pieces fit together exactly as designed, the installation process is faster and smoother, thereby reducing the chances of schedule disruptions.

Just-In-Time Delivery Keeps Projects Moving

Precast companies coordinate closely with contractors to deliver components when they are needed. This reduces site congestion and eliminates delays caused by waiting for materials. Because components are stored at the facility until required, supply chain disruptions are minimized. With just-in-time delivery, construction teams can maintain a steady workflow without interruptions.

Allows Multiple Construction Phases to Overlap

Traditional construction forces crews to work sequentially—waiting for concrete to cure before moving on to the next phase. Precast changes the equation by allowing parallel progress. While the site is being prepared, graded, or outfitted with utilities, precast components are being fabricated simultaneously. This overlap accelerates overall project timelines and ensures the building progresses smoothly from one phase to the next.

Contact Garrett Precast for Quality Concrete Precast Products

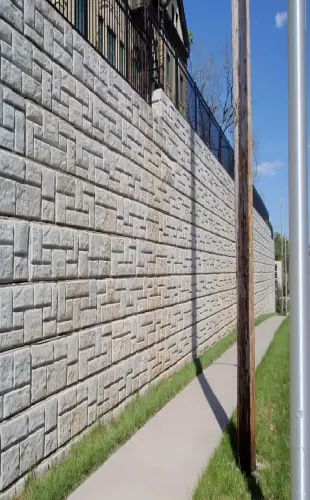

Looking for a trusted company offering concrete precast products? Garrett Precast is a reputable precast company that’s dedicated to providing quality concrete solutions. Our products are not just manufactured with durability in mind; they’re also created to meet the needs of our clients. Some of the concrete precast products we manufacture and supply include retaining walls in Greer, SC, seawalls, septic tanks, septic tank lids, concrete parking stops, and more. Contact us now to place your order and get answers to any questions you may have.