In today’s blog post, we’ll walk you through the numerous applications of precast concrete apart from building sidewalks. The information in this article will help you understand why precast concrete has become more appealing in the construction world. Remember, Garrett Precast is your reliable source for concrete precast products, retaining walls, seawalls, parking stops, septic tanks, and more.

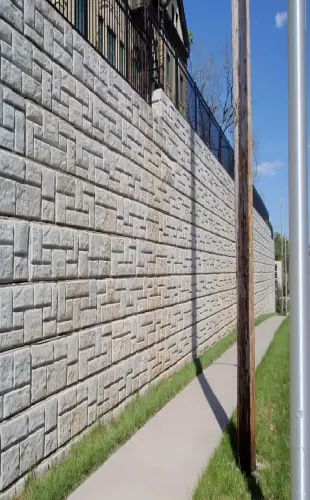

Retaining Walls and Barriers

One of the most common uses of precast concrete beyond sidewalks is for retaining walls and barriers. Precast retaining walls in Spartanburg, SC are ideal for stabilizing sloped areas, preventing soil erosion, and creating usable space in uneven landscapes. They are engineered for strength, and because they’re made in sections, installation is quick. Precast barriers, on the other hand, are used along highways, parking lots, and industrial areas to improve safety and control vehicle flow. Their durability and weight make them reliable for long-term outdoor exposure and heavy-duty performance.

Drainage and Utility Systems

Precast concrete plays a major role in modern drainage and utility infrastructure. Stormwater systems, culverts, manholes, and catch basins made from precast components are vital in managing water flow and preventing flooding. These elements are designed to fit together seamlessly, ensuring watertight connections that last for decades. Precast utility vaults and electrical enclosures also provide safe, weather-resistant housing for power and telecom lines, protecting essential utilities underground.

Architectural and Structural Components

Precast concrete isn’t just practical; it’s also an aesthetic tool for designers. Architectural precast panels are used for building exteriors, providing both insulation and visual appeal. These panels can mimic stone, brick, or custom textures, allowing architects to create stunning facades without the limitations of natural materials. Structural elements such as beams, columns, and floor slabs are also commonly precast, offering strength and consistency that speed up construction while maintaining high quality.

Transportation and Infrastructure Projects

Modern infrastructure depends heavily on precast concrete. Bridges, tunnels, sound walls, and rail platforms use precast sections that can be manufactured to exact specifications. This approach minimizes construction time and disruption to traffic while maintaining strict safety standards. Precast bridge girders, for instance, are built to handle extreme loads and weather conditions, ensuring long-term stability for critical transportation routes.

Residential and Commercial Applications

In homes and commercial spaces, precast concrete finds plenty of creative uses. It’s used for septic tanks, foundation walls, parking stops, stair treads, and decorative landscaping features. Precast panels can also serve as noise barriers or privacy walls around properties. In outdoor living spaces, precast products such as benches, planters, and garden edging add functionality and style with minimal maintenance.

Garrett Precast: Your Go-To Source for Concrete Precast Products

If you’re looking for a professional precast concrete company offering reliable precast products, reach out to Garrett Precast. We do not just manufacture and supply high-quality concrete precast products; we also deliver on time to keep your projects on schedule. We always stay ahead of the curve though continuous innovation and embracing modern technology. Contact us now and let us know which concrete precast products you need.