Today, we’ll compare precast concrete with traditional concrete in terms of strength and explain what makes precast concrete such a reliable choice for modern projects. Remember, Garrett Precast is the name you can trust when you need high-quality concrete precast products.

What Makes Precast Concrete Different

Precast concrete is made in a controlled factory environment, where temperature, curing time, and mix proportions can be managed. Once the concrete sets and hardens, the finished sections are transported to the construction site for installation. This method allows for greater control over quality, which means fewer inconsistencies compared to concrete that’s mixed and poured directly on-site.

Traditional concrete, on the other hand, is mixed and poured where the structure will stand. That may sound straightforward, but it leaves a lot of room for variability. Weather conditions, moisture levels, and even how long the crew waits before finishing can all affect how strong the final product becomes.

Controlled Conditions Make a Difference

When it comes to pure strength, precast concrete has the upper hand. The factory-controlled curing process allows manufacturers to use higher-strength concrete mixes and more efficient curing methods, resulting in a denser and more durable product. Unlike traditional concrete, which may cure unevenly due to changing temperatures or humidity, precast sections achieve their intended strength consistently across the board.

In contrast, traditional concrete’s strength can vary depending on external factors. For example, if it rains shortly after pouring, or if the temperature drops too low during curing, the structural integrity may suffer. Even slight inconsistencies in water-to-cement ratios can lead to cracks, weak spots, or premature surface damage.

Durability and Longevity

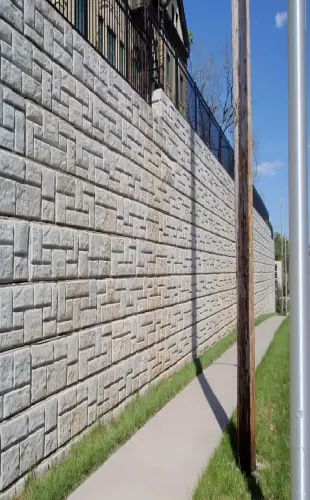

Strength is only part of the equation. Durability in terms of how well the concrete holds up over time is equally important. Precast concrete tends to perform better in this area too. Because it’s cast in reusable molds under strict supervision, the material is more uniform and less porous, which helps resist water penetration, freeze-thaw cycles, and chemical corrosion. This makes precast an excellent choice for structures exposed to harsh conditions, like bridges, retaining walls, parking structures, and marine environments.

Traditional concrete can still be durable, especially when poured and cured properly, but it’s more vulnerable to external factors during construction. Improper curing or exposure to moisture during the early stages can lead to surface scaling or reduced lifespan. In high-stress applications where consistent quality is important, precast concrete outperforms traditional methods.

Efficiency and Environmental Benefits

Apart from strength, precast concrete also offers advantages in efficiency and sustainability. Because components are manufactured ahead of time, construction on-site moves faster and with fewer delays. This not only reduces labor costs but also minimizes disruption to the surrounding area.

From an environmental standpoint, precast plants can recycle water, reuse molds, and manage waste more effectively than on-site mixing operations. Many precast companies also use supplementary materials like fly ash or slag cement, which further reduce the carbon footprint. Traditional concrete can incorporate these eco-friendly measures too, but it’s harder to maintain consistency outside a controlled setting.

The Bottom Line

So, is precast concrete really stronger than traditional concrete? In most cases, yes. Thanks to its controlled production process, higher density, and consistent curing, precast concrete offers greater strength and longevity. However, both materials have their advantages, and the better choice depends on your project goals, timeline, and budget.

Reach Out to Garrett Precast for Concrete Precast Products

Garrett Precast is a top-rated precast company that manufactures and supplies a wide range of products, including retaining walls in Greenville, SC, seawalls, septic tanks, lift stations, and many more. Call us when you’re in need of quality and affordable products built with durability in mind.