Garrett Precast is a professional precast company that manufactures and supplies quality concrete precast products, including retaining walls, seawalls, lift stations, septic tank lids, septic tanks, and many more. If you’re undertaking a residential or commercial construction project, you may be torn between using precast concrete and cast-in-place concrete. Both methods have their advantages, but understanding the differences can help you make the best choice for your project. In this post, we look at the differences between the two types of concrete to help you make an informed decision.

What Is Precast Concrete?

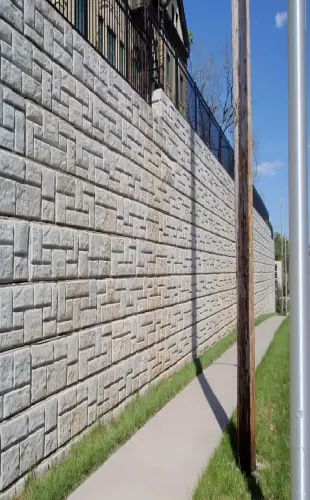

Precast concrete is produced in a controlled manufacturing environment using reusable molds. Once cured and quality-tested, the concrete components are transported to the construction site for quick and easy installation. Because it’s made under precise conditions, precast concrete ensures consistent quality, strength, and performance, no matter the weather or site conditions.

What Is Poured-in-Place Concrete?

Poured-in-place, also known as cast-in-place concrete is mixed and poured directly at the job site. This method gives contractors flexibility to form concrete in custom shapes and sizes that might be difficult to transport. However, site-poured concrete is heavily influenced by environmental factors such as temperature, humidity, and rain, which can affect curing time, finish quality, and overall strength.

Advantages of Precast Concrete

Precast concrete is manufactured in a controlled environment, ensuring consistent mix proportions and curing conditions. This leads to higher strength, greater durability, and resistance to cracking and corrosion compared to site-poured alternatives.

Because precast components are delivered ready to install, on-site labor and construction time are greatly reduced. Projects can progress quickly without waiting for concrete to cure or weather delays to clear up.

While the initial investment in precast may be slightly higher, the reduced labor costs, minimized downtime, and long-term durability make it a cost-effective choice over the life of the project.

- Design Flexibility and Consistency

Precast molds allow for consistent shapes, finishes, and designs, ensuring a uniform look across multiple units. They’re ideal for large-scale developments or infrastructure projects.

Precast manufacturing produces less waste and uses materials efficiently. In addition, products can be recycled or repurposed, supporting environmentally responsible construction practices.

When Poured-in-Place Concrete Makes Sense

Poured-in-place concrete can be beneficial for projects that require custom shapes, seamless monolithic structures, or designs too large to transport as precast components. It’s often used in foundations, slabs, and structural elements where on-site flexibility is important. However, it requires more skilled labor and longer curing times and can be delayed by poor weather conditions.

Which Should You Choose?

If your project demands speed and long-term durability, precast concrete is the better choice. It’s ideal for seawalls, retaining walls in Greenville, SC, lift stations, septic systems, and other modular infrastructure components where consistency and reliability are needed.

On the other hand, if you need a continuous pour for large or complex structural forms, poured-in-place concrete may offer the flexibility you need, though at the cost of time and potential weather-related risks.

Your Local Concrete Precast Products Supplier

Garrett Precast is a top-rated company that offers quality precast solutions at budget-friendly rates. Not only do we offer high-quality products that are built to stand the test of time, but we also deliver them on time to help our clients keep their projects on schedule. Contact us if you have any questions about our concrete precast products, and we’ll get back to you. Our team is on standby to walk you through our product catalog and help you place an order.