In today’s blog post, Garrett Precast—a reputable precast company—looks into the benefits of using precast concrete in modern construction. From retaining walls and seawalls to septic tanks and Infiltrator products, precast concrete offers unmatched strength, versatility, and long-term cost savings that make it a top choice for both residential and commercial applications.

- Superior Quality and Consistency

One of the major advantages of precast concrete is the superior quality it delivers. Since the components are manufactured in a controlled facility, conditions such as temperature, humidity, and curing time can be carefully regulated. This level of control ensures a consistent product that meets or exceeds quality standards every time. Compared to on-site pours that are subject to weather fluctuations and labor inconsistencies, precast components are less prone to defects such as cracks, shrinkage, or air pockets. The result is a more durable and long-lasting structure with fewer maintenance needs down the line.

- Faster Construction Timelines

Time is money in the construction industry, and precast concrete helps save both. Because the elements are made off-site and delivered ready to install, site work and structural fabrication can happen simultaneously. This parallel process reduces the overall construction timeline. In addition, precast panels or blocks can be installed quickly, minimizing labor costs and avoiding weather-related delays. For projects on tight deadlines like schools, hospitals, or commercial facilities, this speed can be a major advantage.

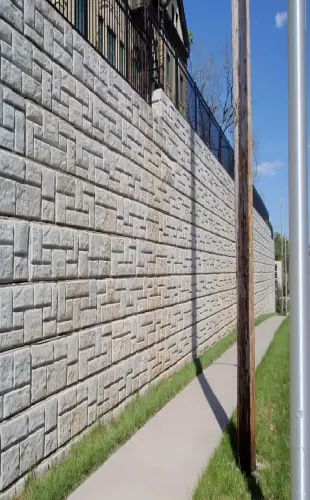

- Design Flexibility and Aesthetic Appeal

Modern precast concrete is far from bland or utilitarian. Today’s technologies allow for a wide range of design choices, from smooth finishes and textures to custom shapes, colors, and architectural details. Whether you're building a contemporary office or a residential complex with ornate facades, precast elements can be designed to meet aesthetic goals without compromising strength. This flexibility allows architects to maintain creative control while ensuring the structural integrity of the building.

Although precast concrete might seem more expensive upfront compared to some traditional methods, it results in long-term savings. Reduced labor costs, faster construction times, and lower maintenance needs all contribute to improved cost efficiency. Furthermore, the durability of precast concrete means fewer repairs and replacements over the lifespan of the structure.

- Environmental Sustainability

Sustainability is a major concern in modern construction, and concrete precast products support this goal in multiple ways. The controlled production process generates less waste, and any unused material can be recycled for future use. Precast components also provide excellent thermal mass, helping to regulate indoor temperatures and reduce the need for heating and cooling. In addition, the durability of precast means fewer materials are needed over time.

- Enhanced Safety and Reduced On-Site Risks

Construction sites are risky environments, but using precast concrete can help mitigate many of those risks. Since the majority of the work is completed off-site, there’s less need for formwork, scaffolding, and high-risk labor on the ground. This reduces the likelihood of accidents and allows for safer and cleaner worksites. Also, the precision involved in manufacturing precast elements leads to fewer installation errors and on-site adjustments.

Reach Out to Garrett Precast for Quality Concrete Precast Products

Looking for a trusted precast company offering a wide range of products? Get in touch with Garrett Precast. We are renowned for manufacturing and supplying a wide range of top-quality products, including grease trap tanks, lift stations, distribution boxes, septic tank risers, septic tank risers, septic tanks, retaining walls in Anderson, SC, concrete parking stops, and more. Browse through our products online or contact us to learn more about our concrete precast products.